In need of a system to provide heat and hot water to its new showroom at Roman Stone Samlesbury in Preston, and with no mains supply gas meaning that a conventional gas boiler would not be an option, Roman Stone approached Horsfield Building Services Engineers Ltd. to design and install an energy efficient heating system.

The new showroom required a system which would reduce the CO2 emissions and keep energy costs as low as possible. Additionally, all capital equipment installed would need to be on the Energy Technology List (ETL) if they were to meet qualifying criteria for the Government sponsored Enhanced Capital Allowance (ECA) scheme. The ECA scheme provides incentives to businesses who invest in eligible energy-saving equipment.

Following a detailed site survey and the completion of the heat load calculations, we recommended the installation of two Daikin ASHP Low Temperature Altherma systems. These would provide low temperature hot water (LTHW) for the underfloor heating on the ground and the first floors. We also recommended a thermodynamic unit which would feed a Heatrae-Sadia Unvented DD145HE Hot Water Cylinder to provide the building with hot water as and when required.

Daikin air source heat pumps are designed to extract heat energy from the outside air and pump it inside to heat indoor spaces, rather than having to generate it from traditional fuel sources. Making use of outside air as a renewable energy resource not only reduces costs, but also leads to a dramatic fall in CO2 emissions.

Unvented water heating is currently one of the fastest growing sectors in the UK market, and the Heatrae-Sadia unvented cylinders provide outstanding levels of hot water performance, as well as comfort and, most importantly, energy saving.

IMPLEMENTATION:

|

|

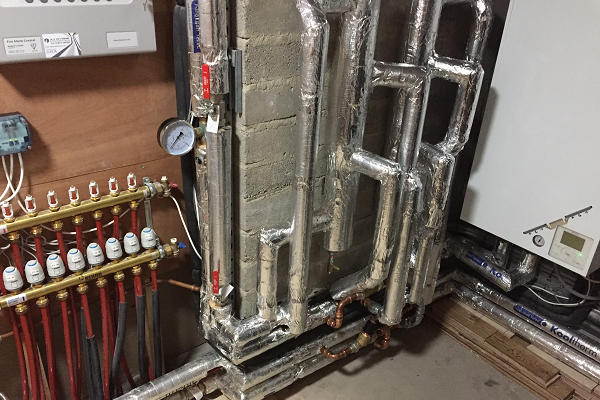

Working closely with the on-site Project Manager and coordinating with the construction company, our team of engineers completed the installation in three phases. Phase One saw the installation of 240m of 16×1.5 Rehau Underfloor Heating Pipework, 160m2 of which ran on the ground floor, and 135m2 on the first floor. We were also able to secure two Daikin ERLQ016CW1 three-phase condensing units to the external wall.

|

|

During the course of Phase Two, we installed all of the refrigerant pipework and two Daikin EHBH16C9W Hydro boxes. Each box supplies its own floor, giving the consumer total control for each particular zone. We were also able to run the first fix of the electrical requirements.

|

|

Finally, in Phase Three, the refrigerant pipework was completed, as well as installation of the control and final electrical requirements. At this stage, we also fitted the Thermodynamic system, which would supply the hot water. This system is able to run independently of the Alterma system, enabling the complete shutdown of the heating system during the warmer months, and so further reducing energy consumption.

|